Genie 2128 Garage Door Opener: A Comprehensive Manual Guide

This guide details the Genie 2128’s operation, maintenance, and safety features, including Aladdin Connect integration and PDF manual access.

The Genie 2128 is a popular, builder-grade garage door opener known for its reliable performance and integration with modern smart home technology. This model boasts Wi-Fi capability, allowing seamless connection with Aladdin Connect for remote control and monitoring.

Designed for convenience and security, the 2128 features a robust belt or chain drive system, offering quieter operation compared to traditional chain-drive openers. Users benefit from included safety features, alongside options like wireless keypads and remote controls.

This comprehensive manual will guide you through installation, programming, maintenance, and troubleshooting, ensuring optimal functionality and longevity of your Genie 2128. Access to the PDF manual is readily available online for detailed reference.

Key Features and Specifications

The Genie 2128 distinguishes itself with integrated Aladdin Connect, enabling Wi-Fi control and monitoring via a smartphone. It offers a robust belt or chain drive system, prioritizing quieter operation. Safety is paramount, featuring safety sensors and a manual release mechanism for emergency use.

Key specifications include compatibility with various garage door sizes and weights. The opener supports wireless keypads and multiple remote controls. It’s designed for easy installation and programming, detailed in the provided operation and maintenance manual.

Accessories, like additional remotes, are available separately. The Genie 2128 balances affordability with smart features, making it a versatile choice for homeowners. Refer to the PDF manual for complete technical details.

Installation and Setup

Proper installation involves unboxing components, securely mounting the unit, and carefully connecting the safety sensors as detailed in the manual.

Unboxing and Component Checklist

Upon receiving your Genie 2128, carefully inspect the box for any shipping damage. Once opened, verify all components are present. You should find the garage door opener unit itself, a rail assembly, a safety sensor set (two sensors), a wireless remote control, a wireless keypad, mounting hardware (brackets, bolts, screws), a user manual, and potentially Aladdin Connect components if included in your package.

Refer to the included manual’s component diagram to confirm everything is accounted for. Missing parts should be reported to Genie customer support immediately. Ensure all protective packaging is removed before proceeding with installation. Keep the original packaging for potential returns or warranty claims. A thorough checklist prevents delays during setup.

Mounting the Genie 2128 Unit

Securely mounting the Genie 2128 is crucial for safe and reliable operation. Begin by assembling the rail sections according to the manual’s instructions. Position the assembled rail within your garage, ensuring adequate headroom and alignment with the garage door. Utilize the provided mounting brackets to attach the rail firmly to ceiling joists or solid structural supports.

Carefully lift the opener unit and attach it to the rail assembly. Double-check all bolts and connections are tightened securely. Proper alignment is essential; misaligned units can cause operational issues. Consult the manual’s diagrams for precise bracket placement and fastening techniques. Prioritize a stable and robust mounting structure.

Connecting the Safety Sensors

The Genie 2128’s safety sensors are vital for preventing accidental door closure on obstructions. Locate the sensor lenses and wiring, typically included in the hardware kit. Mount the sensors approximately six inches above the floor on either side of the garage door opening, ensuring they face each other directly.

Connect the sensor wires to the designated terminals on the opener unit. Verify a solid connection and proper wiring polarity. Test the sensors by breaking the beam – the opener’s indicator light should illuminate. If the light doesn’t activate, re-check wiring and alignment. Proper sensor function is paramount for safety.

Programming and Operation

Explore remote, keypad, and Aladdin Connect programming for the Genie 2128. Learn about the manual release and ensure smooth, safe garage door control.

Remote Control Programming

To program a new remote for your Genie 2128, locate the “Learn” button on the garage door opener motor unit. Press and release this button – a LED indicator will illuminate. Within 30 seconds, press and hold the button on your desired remote control until the garage door opener activates.

This confirms successful programming. Repeat this process for any additional remotes. If the remote doesn’t respond, ensure fresh batteries are installed and repeat the steps. Refer to the full programming, operation, and maintenance manual (available as a PDF download) for detailed diagrams and troubleshooting tips. Always test the remote’s functionality after programming.

Wireless Keypad Programming

Programming the wireless keypad for your Genie 2128 is straightforward. Begin by entering a 4-digit PIN code on the keypad, followed by pressing the “Learn” button on the garage door opener motor unit. The keypad’s indicator light will flash.

Then, enter the same 4-digit PIN code on the keypad again. A successful programming is indicated by the light stopping its flashing. You can change the PIN code at any time by repeating this process with a new code. Consult the PDF manual for detailed instructions and troubleshooting. Ensure the keypad has sufficient battery power for optimal performance.

Aladdin Connect Integration & Setup

The Genie 2128 seamlessly integrates with Aladdin Connect, offering convenient smartphone control. Download the Aladdin Connect app from your app store and create an account. Ensure your opener is Wi-Fi capable – models 2128 and 1128 support this feature.

Follow the in-app instructions to connect your opener to your home’s Wi-Fi network. This typically involves pressing a “Learn” button on the motor unit and entering your Wi-Fi password within the app. Once connected, you can monitor door status, receive alerts, and control the opener remotely. Refer to the PDF manual or Aladdin Connect support for detailed setup guidance.

Using the Manual Release Mechanism

The Genie 2128 features a manual release mechanism for emergency operation during power outages. Locate the red emergency release cord hanging from the garage door opener carriage. Pulling this cord disengages the motor, allowing you to open and close the door manually.

Exercise caution as the door is no longer spring-assisted and may be heavy; After restoring power, re-engage the motor by pulling the cord again until it clicks back into place. Consult the programming, operation & maintenance manual for detailed instructions and safety warnings regarding manual operation. Always test the opener after re-engagement.

Safety Features and Precautions

The Genie 2128 prioritizes safety with features like safety sensors, emergency release, and force settings – refer to the manual for details.

Safety Sensor Troubleshooting

Ensuring proper safety sensor function is crucial for safe operation. If the garage door doesn’t close, verify the sensors are aligned and free of obstructions. Check wiring connections at both sensors and the motor unit – loose connections are a common issue.

Inspect the sensor lenses for dirt or debris; clean them with a soft cloth. A flashing LED on the sensors indicates a problem. Refer to the Genie 2128 manual for specific LED code meanings. If issues persist, temporarily disconnect the sensors (door will operate with caution) to confirm they are the source of the problem. Always re-connect and properly align sensors before regular use.

Remember to consult the manual for detailed diagrams and troubleshooting steps.

Understanding the Opener’s Safety Features

The Genie 2128 prioritizes safety with multiple features. The safety sensors utilize an infrared beam to prevent the door from closing on obstructions. If the beam is broken, the door reverses. The “soft” start and stop feature minimizes jarring movements, enhancing safety.

The rolling code technology prevents unauthorized access by changing the remote’s signal each time it’s used. The manual release allows for operation during power outages, but requires caution; Always consult the Genie 2128 manual for detailed explanations of each feature and proper usage.

Regularly testing these features is vital to ensure continued protection for people and property.

Emergency Operation Procedures

In a power outage, the Genie 2128 can be operated manually. Locate the emergency release cord – refer to your manual for its exact location – and pull it downwards to disengage the carriage. The door can then be lifted and lowered by hand.

Exercise extreme caution as the door is not balanced and can be heavy. After restoring power, re-engage the carriage by pulling the cord upwards until it clicks. Always test the safety sensors after a manual operation to confirm they are functioning correctly.

Consult the Genie 2128 manual for detailed instructions and safety warnings regarding emergency operation.

Maintenance and Troubleshooting

Regular checks, belt/chain maintenance, and addressing common issues—like sensor problems—ensure optimal Genie 2128 performance. See the manual for details.

Regular Maintenance Schedule

To maintain peak performance of your Genie 2128, a consistent maintenance schedule is crucial. Monthly, visually inspect the door tracks for obstructions and ensure smooth operation. Lubricate moving parts – rollers, hinges, and the chain or belt – every six months using a silicone-based lubricant.

Annually, tighten all bolts and nuts, and thoroughly examine the safety sensors for alignment and cleanliness. Check the spring tension (if applicable) and consult a professional if adjustments are needed. Review the opener’s force settings as outlined in the programming manual. Following this schedule will help prevent issues and extend the lifespan of your Genie 2128 opener.

Troubleshooting Common Issues

If your Genie 2128 isn’t responding, first check the power supply and ensure the outlet is functioning. A closed safety sensor is a frequent culprit – verify sensors are aligned and free of obstructions. If the door reverses unexpectedly, adjust the force settings according to the manual.

Remote control issues can often be resolved by reprogramming it, following the instructions in the programming section. For Aladdin Connect problems, confirm your Wi-Fi connection. If the chain or belt is excessively noisy, lubrication may be needed. Consult the full manual for detailed troubleshooting steps and safety precautions before attempting repairs.

Belt/Chain Drive Maintenance

Maintaining the belt or chain drive of your Genie 2128 is crucial for smooth, quiet operation. Regularly inspect the belt or chain for signs of wear, fraying, or damage. Lubrication is key; use a silicone-based lubricant specifically designed for garage door openers – avoid oil-based products.

Apply lubricant sparingly to the belt or chain, avoiding pulleys or gears. Check the tension of the belt or chain; excessive looseness can cause slippage. Periodically inspect the drive system for debris and remove any obstructions. Refer to the manual for specific lubrication intervals and recommended products to ensure optimal performance and longevity.

Advanced Settings and Customization

Customize your Genie 2128 with adjustable travel limits, force settings, and light controls for personalized operation and enhanced convenience.

Adjusting Travel Limits

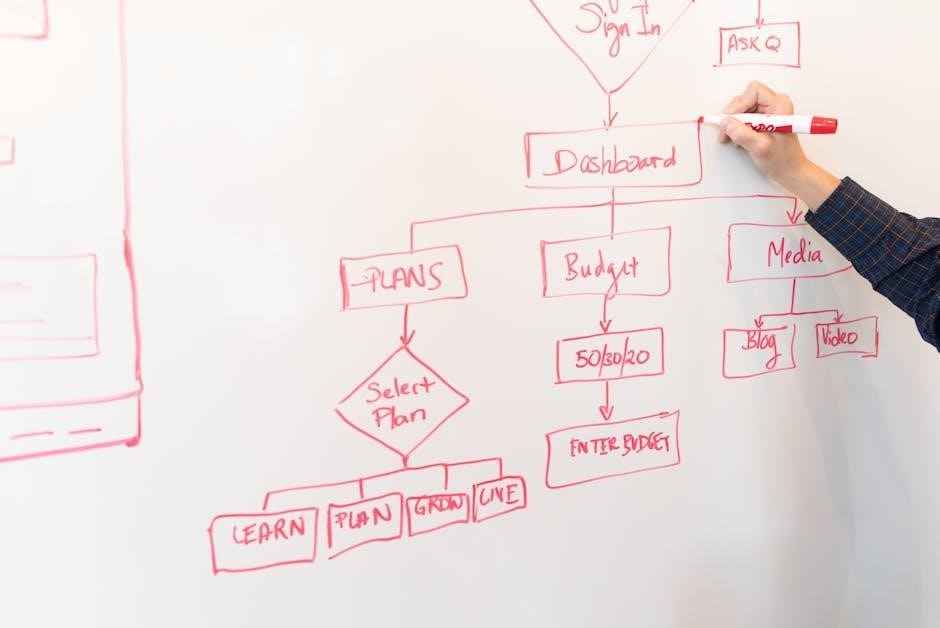

Precisely defining the up and down travel limits of your Genie 2128 is crucial for optimal performance and safety. These adjustments ensure the door opens and closes fully without encountering obstructions or excessive strain. Refer to your programming manual for detailed, step-by-step instructions. Typically, this involves using the adjustment knobs located on the motor unit.

Small, incremental adjustments are recommended; observe the door’s movement after each change. Incorrectly set limits can lead to the door not closing completely, or potentially hitting the ceiling. Always prioritize safety and double-check the settings after any adjustments. The manual provides diagrams illustrating the knob locations and adjustment directions for both up and down travel.

Force Settings Adjustment

The Genie 2128’s force settings dictate the power applied to overcome resistance during door operation. Adjusting these settings is sometimes necessary if the door struggles to open or close, but exercise extreme caution. Incorrect force settings can compromise safety features and potentially cause damage.

Consult the programming manual before making any changes. Typically, adjustments are made via dials on the motor unit. Increase force incrementally, testing after each adjustment. Never exceed the manufacturer’s recommended settings. If significant force is required, investigate the cause – a binding door or broken spring – rather than simply increasing the force. Prioritize safety and proper door maintenance.

Light Control Settings

The Genie 2128 features adjustable light control settings, offering convenience and security. The integrated light can be programmed to automatically turn on with door operation, or manually activated via the remote or wall control. Settings typically include an adjustable auto-off timer, ranging from a few minutes to several hours.

Access light control options through the programming buttons on the motor unit. Refer to the manual for specific button sequences. Some models offer a “vacation mode” that periodically activates the light to simulate occupancy. LED bulbs are recommended for energy efficiency and longevity. Ensure the bulb wattage is compatible with the opener to prevent damage.

Warranty Information

The Genie 2128 comes with a limited warranty covering defects in materials and workmanship. Contact Genie customer support for details and claim procedures.

Genie 2128 Warranty Details

The Genie 2128 garage door opener is protected by a limited warranty, offering peace of mind to owners. This warranty typically covers defects in materials and workmanship under normal use for a specified period. The length of coverage can vary, so reviewing the official warranty documentation is crucial.

Generally, the motor unit itself receives the longest coverage, often a lifetime warranty for the original purchaser. Parts, such as the remote controls and safety sensors, usually have a shorter warranty period, typically one or two years. Labor costs associated with repairs may or may not be included.

To make a warranty claim, retain your proof of purchase and contact Genie customer support. Be prepared to provide the model number, date of purchase, and a detailed description of the issue.

Contacting Genie Customer Support

For assistance with your Genie 2128 garage door opener, several support channels are available. Genie’s official website is a primary resource, offering FAQs, troubleshooting guides, and downloadable manuals. You can often find answers to common questions quickly online.

Direct contact with customer support is possible via phone. Check the Genie website for the most current phone number, as it may vary. Email support is also typically offered, allowing you to submit detailed inquiries and receive responses within a specified timeframe.

When contacting support, have your model number (2128) and proof of purchase readily available. Clearly describe the issue you are experiencing to expedite the assistance process.

Resources and Downloads

Access the Genie 2128 Programming & Operation Manual as a free PDF download. Explore online FAQs and support for comprehensive assistance with your opener.

Downloading the Genie 2128 Manual (PDF)

Accessing the official Genie 2128 manual in PDF format is straightforward and provides a comprehensive resource for all your needs; ManualsLib hosts a readily available version of the Programming, Operation & Maintenance Manual, ensuring you have detailed instructions at your fingertips;

This downloadable guide covers everything from initial setup and programming of remote controls and keypads to troubleshooting common issues and understanding safety features. The PDF format allows for easy viewing on any device and convenient offline access.

Ensure you have the latest version for accurate information regarding Aladdin Connect integration and specific model functionalities. A direct link to the PDF can often be found through Genie’s official support channels as well.

Accessing Online Support and FAQs

Genie provides extensive online support resources to assist with your 2128 garage door opener. Their official website features a dedicated support section with frequently asked questions (FAQs) addressing common concerns and troubleshooting steps.

You can find helpful articles, videos, and diagrams to guide you through installation, programming, and maintenance procedures. Aladdin Connect support is also readily available online, offering assistance with Wi-Fi connectivity and smart home integration.

For more personalized assistance, Genie’s customer support team can be contacted directly through their website or by phone. Utilizing these online resources can often resolve issues quickly and efficiently, minimizing downtime and maximizing convenience.